Insulation treatment is a key factor in the reliability of motor products. In any motor manufacturing company, the insulation treatment process of windings is a key point of quality control. The quality of the insulating paint itself and the process control effect all affect the motor to varying degrees. reliability and efficiency levels.

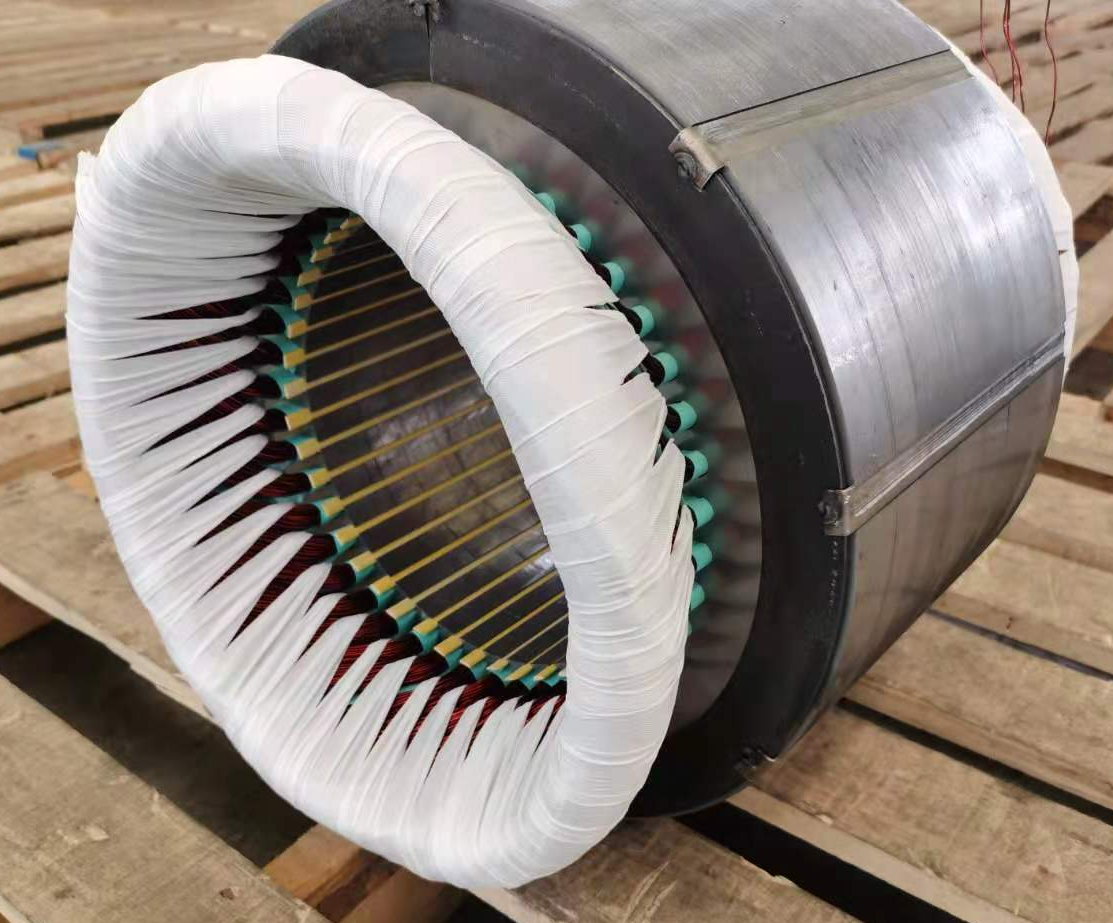

During the motor manufacturing process, the windings are insulated. On the one hand, it is to strengthen the insulation performance of the windings and prevent the occurrence of phase-to-phase, inter-turn and ground faults. On the other hand, it is to solidify the windings into a tight whole to effectively control the motor. The level of vibration and noise also plays a very important role, which is to improve the efficiency of the motor.

During the operation of the motor, the heat generated by the windings needs to be dissipated through special channels, and the insulation between the windings is naturally an important medium that must pass through. With good heat dissipation effect, the temperature of the windings will be relatively low, which naturally reduces the heat of the motor. losses, thereby improving the efficiency level of the motor. Therefore, how to ensure the insulation treatment effect of motor windings is the key to motor reliability and performance optimization.

In some cases of motor disposal with high temperature, many manufacturers will solve the problem through the improvement of insulation treatment process. In the insulation treatment of motor windings, more motor manufacturers use VPI vacuum dipping, rotary baking, etc. The process improves the insulation process.

In terms of the selection of insulating paint, higher adhesion, better fluidity, and fast curing effect have become the focus of attention of motor manufacturers and repairers.

Some motors have a higher temperature rise. After being dipped in paint again, the temperature rise index will be improved to a certain extent. High-quality insulating paint is more conducive to the optimization and guarantee of motor performance.

Post time: Oct-15-2024