The increasing demand for electrical energy to sustain global development requires consistent heavy investment in power supply generation. However, in addition to complex medium and long term planning, these investments rely on natural resources, which are

becoming depleted due to constant pressures upon the environment. The best strategy, therefore, to maintain energy supply in the short term is to avoid wastage and increase energy efficiency. Electric motors play a major role in this strategy; since around 40%

of global energy demand is estimated to be related to electric motor applications.

As a consequence of this need to reduce energy consumption and carbon dioxide emissions, many Governments worldwide have imposed local Regulations, also known as MEPS (Minimum Energy Performance Standards) to numerous types of equipment,

including electric motors.

Whilst the specific requirements of these MEPS differ slightly between countries, the implementation of regional standards such as ABNT, IEC, MG-1, which define the efficiency levels and test methods to determine these efficiencies, allow a standardization of the definition, measurement and publication format for efficiency data amongst motor manufacturers, simplifying the correct motors’ selection.

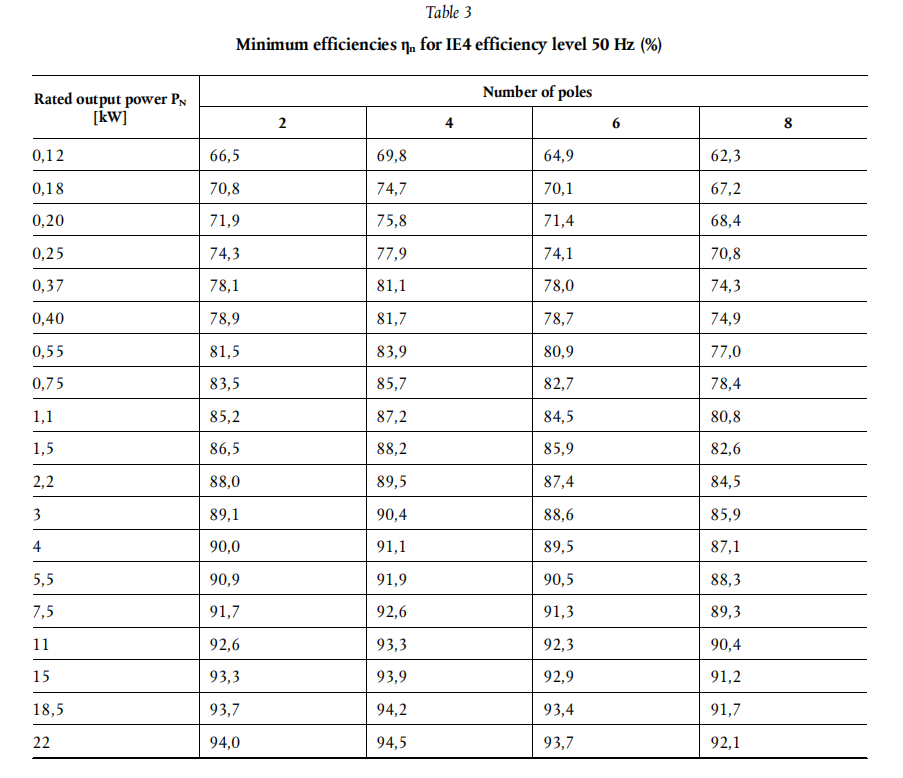

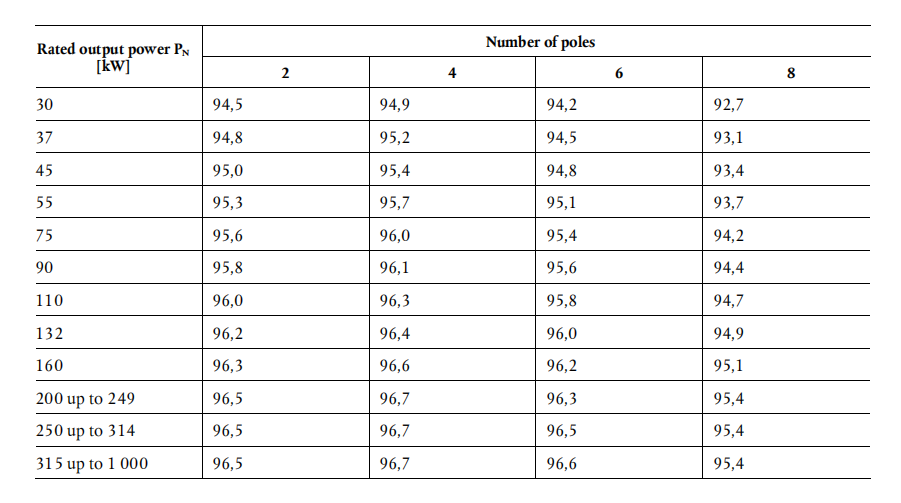

the energy efficiency of three-phase motors which are not brake motors, Ex eb increased safety motors, or other

explosion-protected motors, with a rated output equal to or above 75 kW and equal to or below 200 kW, with

2, 4, or 6 poles, shall correspond to at least the IE4 efficiency level set out in Table 3.

To determine the minimum efficiency of 50 Hz motors with rated power outputs PN of between 0,12 and 200 kW not provided in Tables 1, 2 and 3, the following formula shall be used:

ηn = A* [log1o(Pv/1kW)]3 + B X [log10(PN/1kW)]2 + C* log10(PN/1kW)+ D.

A, B, C and D are interpolation coefficients to be determined according to Tables 4 and 5.

Post time: Oct-12-2022