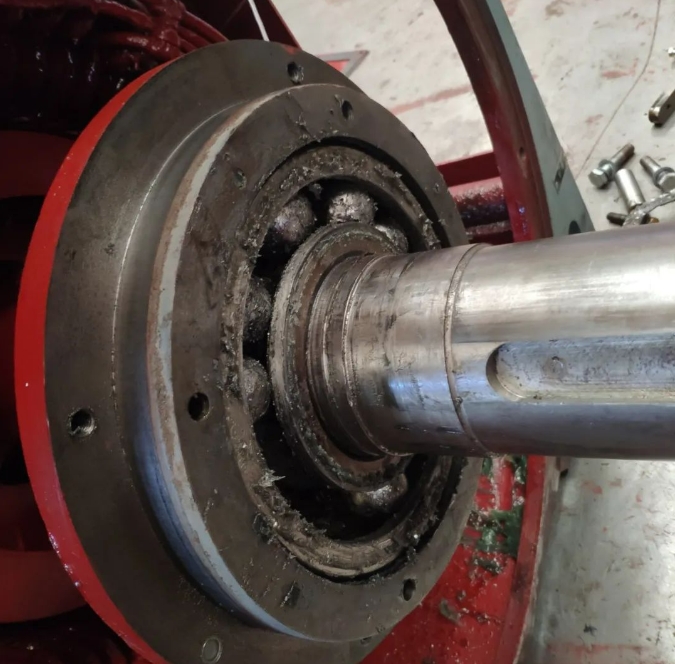

Shaft current is a common and unavoidable problem for high-voltage motors and variable-frequency motors. Shaft current can cause great damage to the bearing system of the motor. For this reason, many motor manufacturers use insulating bearing systems or bypass measures to avoid shaft current problems. The generation of shaft current is due to the passage of a time-varying magnetic flux through the circuit composed of the motor’s shaft, bearings, and bearing chamber, which induces shaft voltage on the shaft and generates current when the circuit is turned on. It is a low-voltage, high-current physical phenomenon that causes great damage to the motor’s bearing system and will destroy the bearings in a short period of time due to electro-erosion. The motor core punching is a fan-shaped sheet with slots that are positioned with the base. The split core of a large motor and the eccentricity of the rotor are key factors in the generation of shaft current. Therefore, shaft current becomes the main problem for large motors.

In order to avoid the shaft current problem, necessary measures should be taken in the selection and design of parts and components to theoretically eliminate the factors that generate shaft current. The number of seams S on the circumference is controlled and adjusted by the relationship between S and the greatest common divisor t of the number of motor pole pairs. When S/t is an even number, the conditions for generating shaft voltage are not met, and naturally there will be no shaft current; when S/t is an odd number, it is very likely that shaft voltage will be generated, and shaft current will be generated. Even if this type of motor is an industrial frequency motor, there will be shaft current problems. Therefore, for large motors, measures to avoid shaft current are generally taken.

In addition, the high-order harmonics of variable frequency motors are also one of the reasons for the shaft current. No matter how powerful the variable frequency motor is, there may be shaft current, so many small-power variable frequency motors will use insulated bearings, while most high-power motors will use insulated end covers, or take insulation measures on the shaft bearing position; in order to ensure the compatibility of variable frequency motors and ordinary industrial frequency motor parts, some manufacturers will take bypass measures at the bearing cover position.

Post time: Aug-20-2024